EVs Will Drive A Lithium Supply Crunch

A carbon-cost-free long term will have to have many hundreds of thousands of batteries, the two to drive electric motor vehicles and to shop wind and photo voltaic energy on the grid. Today’s battery chemistries mostly rely on lithium—a metal that could soon experience a international provide crunch. Some analysts warn that as EV creation soars, lithium producers won’t be capable to hold up with demand. That could briefly pump the brakes on the world’s thoroughly clean electrical power ambitions, they say.

How huge the lithium scarcity will be, and how substantially turmoil it will lead to, is much from specific.

Just lately, Rystad Electricity projected a “serious lithium provide deficit” in 2027 as mining capacity lags behind the EV growth. The mismatch could effectively delay the creation of all around three.three million battery-driven passenger automobiles that yr, in accordance to the exploration business. Without the need of new mining assignments, delays could swell to the equal of twenty million automobiles in 2030. Battery-driven buses, vehicles, ships, and grid storage systems will also sense the squeeze.

“A significant disruption is brewing for electric automobile makers,” James Ley, senior vice president of Rystad’s electrical power metals group in London, explained in a news release. “Although there is a good deal of lithium to mine in the ground, the present and prepared assignments will not be adequate to fulfill demand for the metal.”

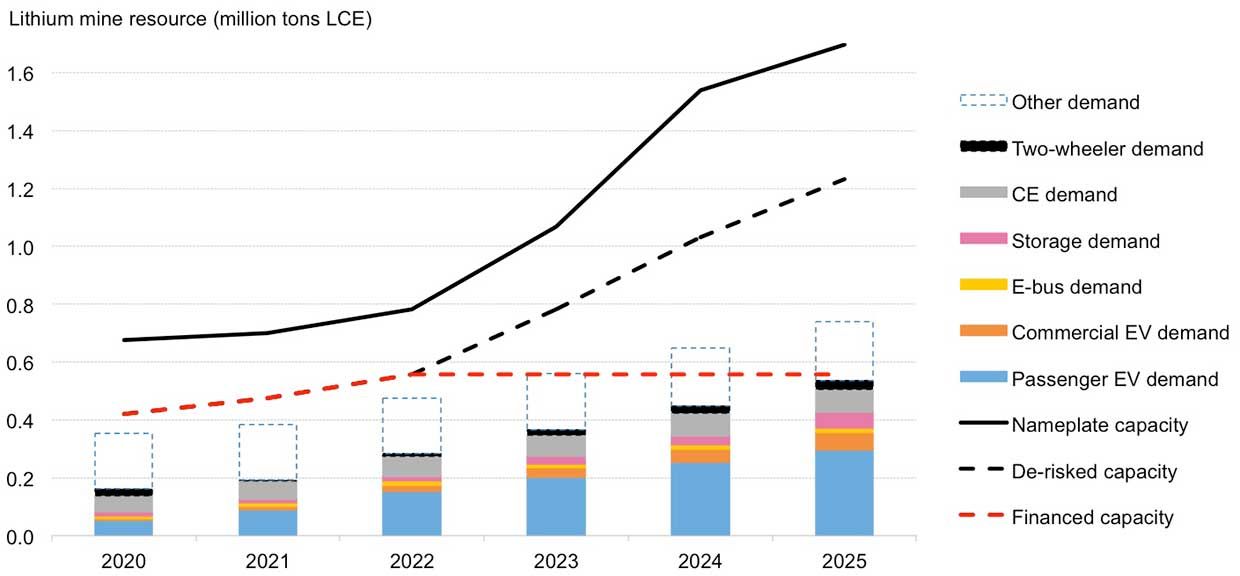

A lithium deficit would flip what is at present a surplus. Demand from battery makers is now about three hundred,000 metric tons of lithium carbonate equal (LCE) per yr, though there is 520,000 metric tons of present mining capacity for battery marketplaces. Rystad’s analysis displays that demand from makers could get to two.eight million metric tons in 2028. Nevertheless, mining capacity is only predicted to get to about two million metric tons that yr, assuming no new mining assignments are included to the current pipeline.

A entire world in which EV assembly strains gather dust though battery makers scrabble for scraps of lithium is wholly avoidable. But for producers, the remedy is not as very simple as mining more difficult rock—called spodumene—or tapping more underground brine deposits to extract lithium. That is because most of the better, much easier-to-exploit reserves are previously spoken for in Australia (for difficult rock) and in Chile and Argentina (for brine). To considerably scale capacity, producers will also will need to exploit the world’s “marginal” resources, which are costlier and more electrical power-intense to produce than regular counterparts.

“It’s not that it’s a useful resource issue. There is no dread that there is not adequate lithium to fulfill demand by 2030 or lengthier,” Sophie Lu, the head of metals and mining for BloombergNEF (BNEF), explained by phone from Sydney. The larger sized problem, she explained, is whether the field can continue producing lithium at very similar costs as currently, though also diversifying provide chains absent from today’s dominant geographies and doing so without causing environmental damage.

In its latest outlook, published Wednesday, BNEF explained there are adequate lithium assignments in the pipeline to fulfill demand out to the late 2020s—assuming assignments are efficiently financed and formulated. But a provide deficit may possibly kick in all around 2028, Lu explained. Virtually $fourteen billion is even now necessary to finance the pipeline of lithium creation capacity out to 2025, nevertheless this pipeline surpasses BNEF’s forecast for demand by that yr.

Considerations about provide constraints are driving innovation in the lithium field. A handful of assignments in North The usa and Europe are piloting and tests “direct lithium extraction,” an umbrella expression for systems that, commonly speaking, use electrical power and chemical processes to isolate and extract concentrated lithium. So-named DLE could revolutionize the field, akin to how the SX/EW (solvent extraction-electrowinning) method has transformed the copper field, or how electric arc furnaces have enabled metal creation employing electrical power as a substitute of coal.

In southwestern Germany, Vulcan Electricity is extracting lithium from geothermal springs that bubble thousands of meters beneath the Rhine river. The startup commenced working its initially pilot plant in mid-April. Vulcan explained it could be extracting 15,000 metric tons of lithium hydroxide—a compound applied in battery cathodes—per yr. In southern California, Managed Thermal Means is building a geothermal energy plant and lithium extraction facility at the Salton Sea. The company explained a pilot facility will get started producing twenty,000 metric tons per yr of lithium hydroxide, also by 2024.

A further way to boost lithium supplies is to recuperate the metal from used batteries, of which there is previously enough provide. Right now, significantly less than five percent of all used lithium-ion batteries are recycled, in large component because the packs are difficult and highly-priced to dismantle. A lot of batteries now end up in landfills, leaching chemicals into the setting and wasting usable elements. But Lu explained the field is very likely to ramp up recycling after 2028, when the supply deficit kicks in. Developers are previously starting up to build new amenities, which include a $a hundred seventy five million plant in Rochester, N.Y. When concluded, it will be North America’s major recycling plant for lithium-ion batteries.

Further into the long term, however, the outlook for lithium will get rocky.

Researchers in Finland and Germany just lately modeled 18 eventualities for when lithium resources may possibly in fact be depleted. They regarded various assumptions about how substantially lithium is even now accessible in the world’s brines, rocks, oilfields, and other normal features. A scenario with “very high” amounts of lithium, or 73 million metric tons, would see lithium completely depleted shortly after 2100. That is if three billion EVs hit the road and if the entire world takes sturdy ways to recycle batteries, use automobile-to-grid programs, and produce next-life battery makes use of.

Lithium availability “will turn out to be a major danger to the very long-expression sustainability of the transport sector except a combine of steps is taken to ameliorate the obstacle,” the scientists wrote in the 2020 review. This sort of steps involve building new battery chemistries, producing more artificial fuels, and making more railways—options that really do not have to have lithium.