Enevate’s Silicon Anodes Could Yield EV Batteries That Run 400 km on a 5-Minute Charge

Battery makers have for decades been attempting to swap the graphite anode in lithium-ion batteries with a variation manufactured of silicon, which would give electric automobiles a substantially lengthier selection. Some batteries with silicon anodes are getting near to current market for wearables and electronics. The recipes for these silicon-wealthy anodes that a handful of providers are building commonly use silicon oxide or a blend of silicon and carbon.

But Irvine, CA-based Enevate is making use of an engineered porous movie manufactured generally of pure silicon. In addition to currently being low-cost, the new anode content, which founder and chief technologies officer Benjamin Park has invested far more than ten decades building, will direct to an electric motor vehicle (EV) that has 30 percent far more selection on a one demand than today’s EVs. What is far more, the battery Enevate envisions could be billed up enough in 5 minutes to deliver 400 km of driving selection.

Massive names in the battery and automotive business are listening. Carmakers Renault, Nissan, and Mitsubishi, as properly as battery-makers LG Chem and Samsung, are buyers. And lithium battery pioneer and 2019 Chemistry Nobel Prize winner John Goodenough is on the company’s Advisory Board.

When lithium-ion batteries are billed, lithium ions go from the cathode to the anode. The far more ions the anode can hold, the larger its strength potential, and the lengthier the battery can run. Silicon can in theory hold 10 instances the strength of graphite. But it also expands and contracts drastically, falling apart soon after a couple of demand cycles.

To get around that, battery makers these kinds of as Tesla right now increase just a small little bit of silicon to graphite powder. The powder is combined with a glue-like plastic known as a binder and is coated on a thin copper foil to make the anode. But, says Park, lithium ions respond with silicon first, just before graphite. “The silicon nevertheless expands rather a little bit, and that plastic binder is weak,” he says, detailing that the full electrode is far more very likely to degrade as the total of silicon is ramped up.

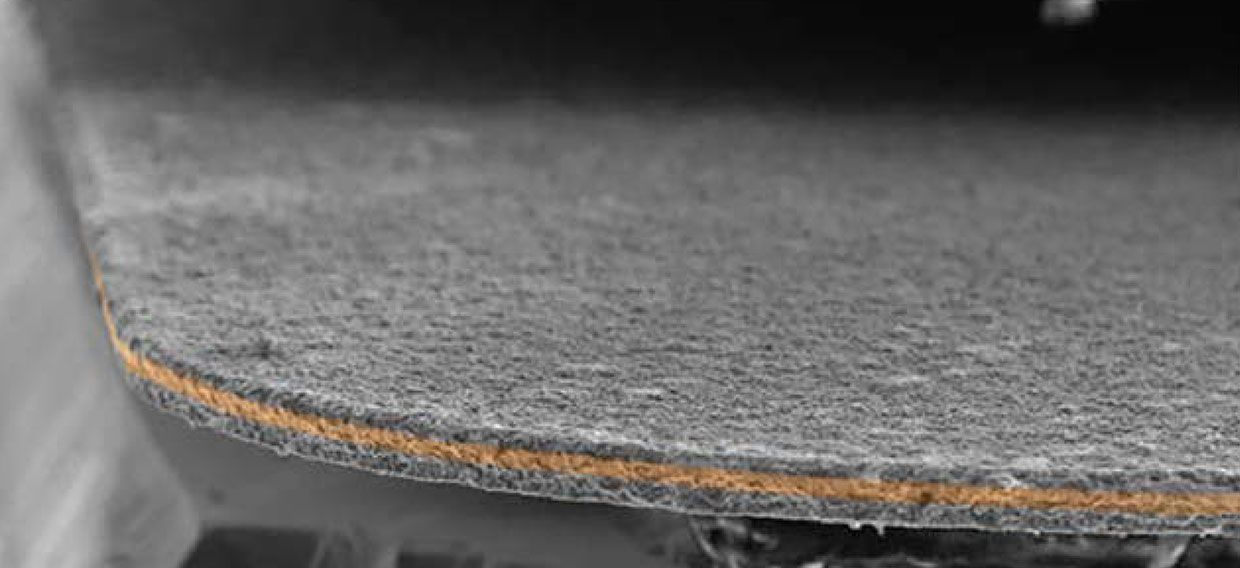

Enevate does not use plastic binders. As a substitute, its patented process makes the porous ten- to sixty-µm-thick silicon movie specifically on a copper foil. The cherry on leading is a nanometers-thick protective coating, which, says Park, “prevents the silicon from reacting with the electrolyte.” That type of reaction can also problems a battery.

The process does not need significant-quality silicon, so anodes of this type cost less than their graphite counterparts of the same potential. And because the content is largely silicon, lithium ions can slip in and out extremely quickly, charging the battery to seventy five percent of its potential in 5 minutes, with no leading to substantially expansion. Park likens it to a significant-potential motion picture theater. “If you have a complete motion picture theater it usually takes a prolonged time to come across the one empty seat. We have a theater with 10 instances far more potential. Even if we fill that theater halfway, [it nevertheless doesn’t take prolonged] to come across empty seats.”

The company’s roll-to-roll processing tactics can make silicon anodes quickly ample for significant-quantity manufacturing, says Park. By coupling the silicon anode with standard cathode supplies these kinds of as nickel-manganese-cobalt, they have manufactured battery cells with strength densities as significant as 350 watt-several hours per kilogram, which is about 30 percent far more than the precise strength of today’s lithium-ion batteries. Enevate says it is now operating with multiple significant automotive providers to develop typical-sizing battery cells for 2024-twenty five product yr EVs.