Study: Recycled Lithium Batteries as Good as Newly Mined

The way the inspections are done has changed little as well.

Historically, checking the condition of electrical infrastructure has been the responsibility of men walking the line. When they’re lucky and there’s an access road, line workers use bucket trucks. But when electrical structures are in a backyard easement, on the side of a mountain, or otherwise out of reach for a mechanical lift, line workers still must belt-up their tools and start climbing. In remote areas, helicopters carry inspectors with cameras with optical zooms that let them inspect power lines from a distance. These long-range inspections can cover more ground but can’t really replace a closer look.

Recently, power utilities have started using drones to capture more information more frequently about their power lines and infrastructure. In addition to zoom lenses, some are adding thermal sensors and lidar onto the drones.

Thermal sensors pick up excess heat from electrical components like insulators, conductors, and transformers. If ignored, these electrical components can spark or, even worse, explode. Lidar can help with vegetation management, scanning the area around a line and gathering data that software later uses to create a 3-D model of the area. The model allows power system managers to determine the exact distance of vegetation from power lines. That’s important because when tree branches come too close to power lines they can cause shorting or catch a spark from other malfunctioning electrical components.

AI-based algorithms can spot areas in which vegetation encroaches on power lines, processing tens of thousands of aerial images in days.Buzz Solutions

Bringing any technology into the mix that allows more frequent and better inspections is good news. And it means that, using state-of-the-art as well as traditional monitoring tools, major utilities are now capturing more than a million images of their grid infrastructure and the environment around it every year.

AI isn’t just good for analyzing images. It can predict the future by looking at patterns in data over time.

Now for the bad news. When all this visual data comes back to the utility data centers, field technicians, engineers, and linemen spend months analyzing it—as much as six to eight months per inspection cycle. That takes them away from their jobs of doing maintenance in the field. And it’s just too long: By the time it’s analyzed, the data is outdated.

It’s time for AI to step in. And it has begun to do so. AI and machine learning have begun to be deployed to detect faults and breakages in power lines.

Multiple power utilities, including

Xcel Energy and Florida Power and Light, are testing AI to detect problems with electrical components on both high- and low-voltage power lines. These power utilities are ramping up their drone inspection programs to increase the amount of data they collect (optical, thermal, and lidar), with the expectation that AI can make this data more immediately useful.

My organization,

Buzz Solutions, is one of the companies providing these kinds of AI tools for the power industry today. But we want to do more than detect problems that have already occurred—we want to predict them before they happen. Imagine what a power company could do if it knew the location of equipment heading towards failure, allowing crews to get in and take preemptive maintenance measures, before a spark creates the next massive wildfire.

It’s time to ask if an AI can be the modern version of the old Smokey Bear mascot of the United States Forest Service: preventing wildfires

before they happen.

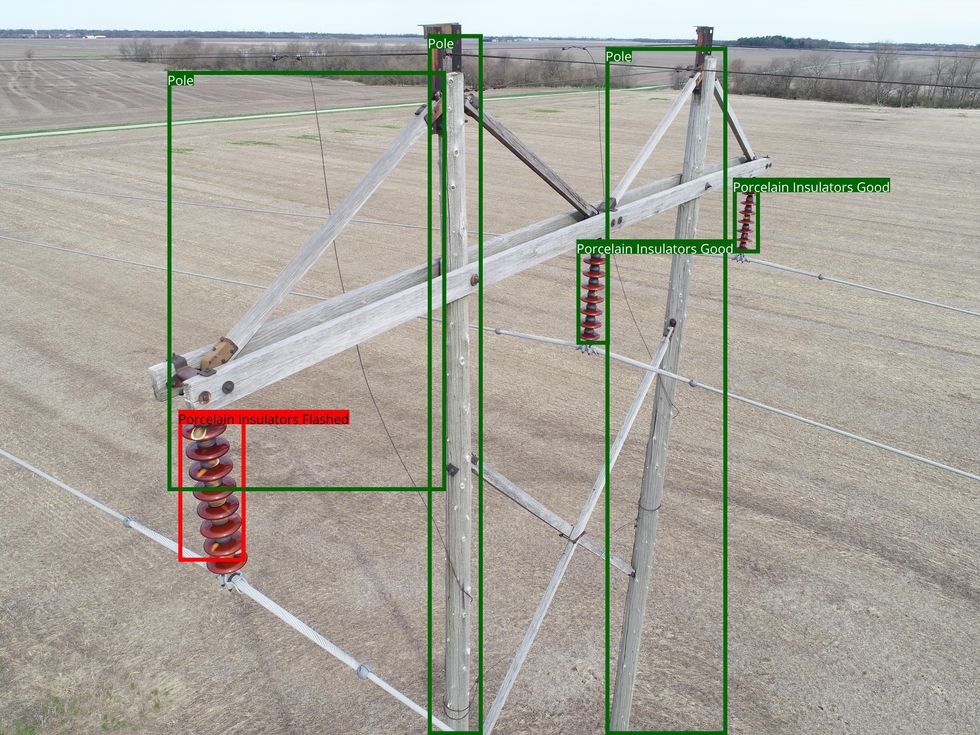

Damage to power line equipment due to overheating, corrosion, or other issues can spark a fire.Buzz Solutions

We started to build our systems using data gathered by government agencies, nonprofits like the

Electrical Power Research Institute (EPRI), power utilities, and aerial inspection service providers that offer helicopter and drone surveillance for hire. Put together, this data set comprises thousands of images of electrical components on power lines, including insulators, conductors, connectors, hardware, poles, and towers. It also includes collections of images of damaged components, like broken insulators, corroded connectors, damaged conductors, rusted hardware structures, and cracked poles.

We worked with EPRI and power utilities to create guidelines and a taxonomy for labeling the image data. For instance, what exactly does a broken insulator or corroded connector look like? What does a good insulator look like?

We then had to unify the disparate data, the images taken from the air and from the ground using different kinds of camera sensors operating at different angles and resolutions and taken under a variety of lighting conditions. We increased the contrast and brightness of some images to try to bring them into a cohesive range, we standardized image resolutions, and we created sets of images of the same object taken from different angles. We also had to tune our algorithms to focus on the object of interest in each image, like an insulator, rather than consider the entire image. We used machine learning algorithms running on an artificial neural network for most of these adjustments.

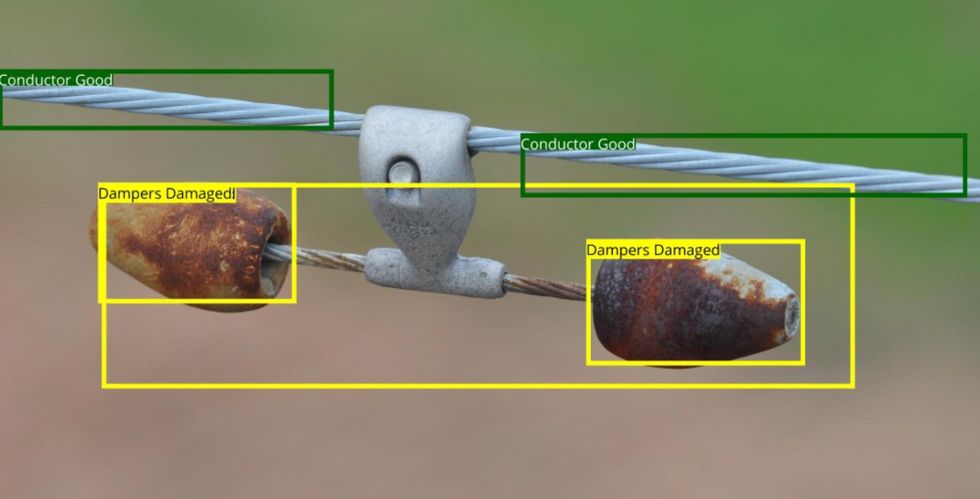

Today, our AI algorithms can recognize damage or faults involving insulators, connectors, dampers, poles, cross-arms, and other structures, and highlight the problem areas for in-person maintenance. For instance, it can detect what we call flashed-over insulators—damage due to overheating caused by excessive electrical discharge. It can also spot the fraying of conductors (something also caused by overheated lines), corroded connectors, damage to wooden poles and crossarms, and many more issues.

Developing algorithms for analyzing power system equipment required determining what exactly damaged components look like from a variety of angles under disparate lighting conditions. Here, the software flags problems with equipment used to reduce vibration caused by winds.Buzz Solutions

But one of the most important issues, especially in California, is for our AI to recognize where and when vegetation is growing too close to high-voltage power lines, particularly in combination with faulty components, a dangerous combination in fire country.

Today, our system can go through tens of thousands of images and spot issues in a matter of hours and days, compared with months for manual analysis. This is a huge help for utilities trying to maintain the power infrastructure.

But AI isn’t just good for analyzing images. It can predict the future by looking at patterns in data over time. AI already does that to predict

weather conditions, the growth of companies, and the likelihood of onset of diseases, to name just a few examples.

We believe that AI will be able to provide similar predictive tools for power utilities, anticipating faults, and flagging areas where these faults could potentially cause wildfires. We are developing a system to do so in cooperation with industry and utility partners.

We are using historical data from power line inspections combined with historical weather conditions for the relevant region and feeding it to our machine learning systems. We are asking our machine learning systems to find patterns relating to broken or damaged components, healthy components, and overgrown vegetation around lines, along with the weather conditions related to all of these, and to use the patterns to predict the future health of the power line or electrical components and vegetation growth around them.

Buzz Solutions’ PowerAI software analyzes images of the power infrastructure to spot current problems and predict future ones

Right now, our algorithms can predict six months into the future that, for example, there is a likelihood of five insulators getting damaged in a specific area, along with a high likelihood of vegetation overgrowth near the line at that time, that combined create a fire risk.

We are now using this predictive fault detection system in pilot programs with several major utilities—one in New York, one in the New England region, and one in Canada. Since we began our pilots in December of 2019, we have analyzed about 3,500 electrical towers. We detected, among some 19,000 healthy electrical components, 5,500 faulty ones that could have led to power outages or sparking. (We do not have data on repairs or replacements made.)

Where do we go from here? To move beyond these pilots and deploy predictive AI more widely, we will need a huge amount of data, collected over time and across various geographies. This requires working with multiple power companies, collaborating with their inspection, maintenance, and vegetation management teams. Major power utilities in the United States have the budgets and the resources to collect data at such a massive scale with drone and aviation-based inspection programs. But smaller utilities are also becoming able to collect more data as the cost of drones drops. Making tools like ours broadly useful will require collaboration between the big and the small utilities, as well as the drone and sensor technology providers.

Fast forward to October 2025. It’s not hard to imagine the western U.S facing another hot, dry, and extremely dangerous fire season, during which a small spark could lead to a giant disaster. People who live in fire country are taking care to avoid any activity that could start a fire. But these days, they are far less worried about the risks from their electric grid, because, months ago, utility workers came through, repairing and replacing faulty insulators, transformers, and other electrical components and trimming back trees, even those that had yet to reach power lines. Some asked the workers why all the activity. “Oh,” they were told, “our AI systems suggest that this transformer, right next to this tree, might spark in the fall, and we don’t want that to happen.”

Indeed, we certainly don’t.