Has Fusion Really Had Its “Wright Brothers” Moment?

Even so, even though laptop or computer chips is not going to burn a literal hole in your pocket (although they do get very hot adequate to

fry an egg), they still need a ton of latest to run the applications we use each and every day. Take into account the knowledge-centre SoC: On ordinary, it is consuming two hundred W to present its transistors with about 1 to two volts, which indicates the chip is drawing one hundred to two hundred amperes of latest from the voltage regulators that source it. Your standard fridge draws only 6 A. Substantial-stop cellular phones can draw a tenth as a great deal electricity as knowledge-centre SoCs, but even so that is still about 10–20 A of latest. That is up to 3 fridges, in your pocket!

Providing that latest to billions of transistors is rapidly getting to be a single of the significant bottlenecks in large-effectiveness SoC structure. As transistors go on to be made tinier, the interconnects that source them with latest will have to be packed ever closer and be made ever finer, which raises resistance and saps electricity. This can’t go on: With no a massive adjust in the way electrons get to and from products on a chip, it is not going to issue how a great deal smaller sized we can make transistors.

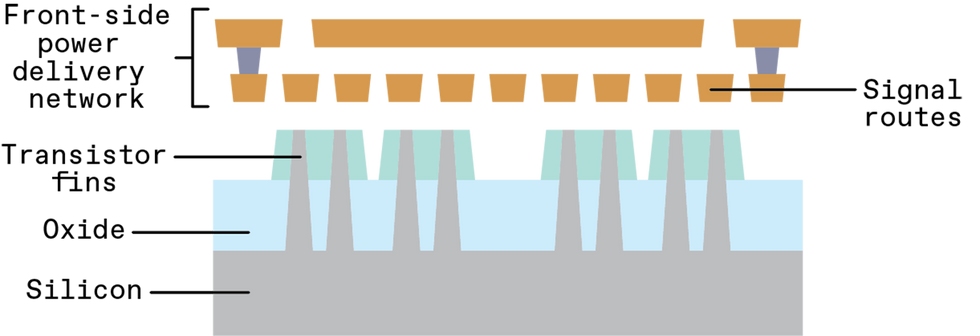

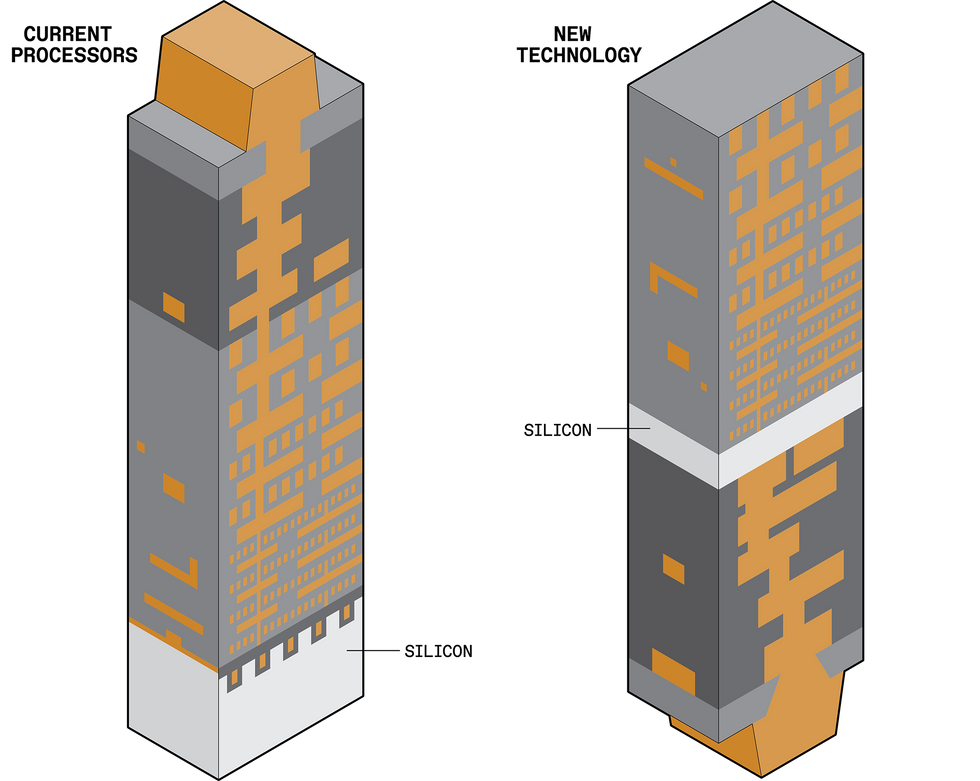

In present day processors both equally signals and electricity achieve the silicon [light-weight gray] from earlier mentioned. New technology would independent individuals features, preserving electricity and generating far more room for signal routes [suitable].Chris Philpot

Thankfully, we have a promising option: We can use a side of the silicon that is extensive been disregarded.

Electrons have to travel a extensive way to get from the supply that is producing them to the transistors that compute with them. In most electronics they travel alongside the copper traces of a printed circuit board into a offer that holds the SoC, as a result of the solder balls that link the chip to the

offer, and then via on-chip interconnects to the transistors themselves. It is really this last stage that truly matters.

To see why, it aids to recognize how chips are made. An SoC starts as a bare piece of large-quality, crystalline silicon. We initially make a layer of transistors at the extremely major of that silicon. Upcoming we url them with each other with metal interconnects to kind circuits with practical computing features. These interconnects are fashioned in levels identified as a stack, and it can just take a ten-to-20-layer stack to provide electricity and knowledge to the billions of transistors on present day chips.

These levels closest to the silicon transistors are slender and tiny in buy to link to the very small transistors, but they grow in size as you go up in the stack to increased degrees. It is really these degrees with broader interconnects that are much better at delivering electricity mainly because they have significantly less resistance.

These days, both equally electricity and signals achieve transistors from a community of interconnects earlier mentioned the silicon (the “entrance side”). But growing resistance as these interconnects are scaled down to ever-finer dimensions is generating that scheme untenable.Chris Philpot

You can see, then, that the metal that powers circuits—the electricity shipping community (PDN)—is on major of the transistors. We refer to this as entrance-side electricity shipping. You can also see that the electricity community unavoidably competes for area with the community of wires that provides signals, mainly because they share the same established of copper assets.

In buy to get electricity and signals off of the SoC, we ordinarily link the uppermost layer of metal—farthest away from the transistors—to solder balls (also identified as bumps) in the chip offer. So for electrons to achieve any transistor to do practical work, they have to traverse ten to 20 levels of increasingly narrow and tortuous metal until eventually they can last but not least squeeze as a result of to the extremely last layer of local wires.

This way of distributing electricity is basically lossy. At each and every stage alongside the path, some electricity is dropped, and some will have to be used to handle the shipping alone. In present day SoCs, designers ordinarily have a spending budget that allows decline that prospects to a ten percent reduction in voltage amongst the offer and the transistors. Hence, if we strike a full efficiency of 90 percent or better in a electricity-shipping community, our designs are on the suitable track.

Historically, this kind of efficiencies have been achievable with good engineering—some may well even say it was quick compared to the challenges we encounter these days. In present day electronics, SoC designers not only have to manage growing electricity densities but to do so with interconnects that are dropping electricity at a sharply accelerating price with every new era.

You can structure a back-side electricity shipping community that is up to 7 times as effective as the traditional entrance-side community.

The growing lossiness has to do with how we make nanoscale wires. That course of action and its accompanying components trace back to about 1997, when IBM commenced to make interconnects out of copper in its place of aluminum, and the industry shifted alongside with it. Up until eventually then aluminum wires experienced been fine conductors, but in a number of far more measures alongside the

Moore’s Regulation curve their resistance would quickly be as well large and turn out to be unreliable. Copper is far more conductive at modern IC scales. But even copper’s resistance commenced to be problematic once interconnect widths shrank beneath one hundred nanometers. These days, the smallest produced interconnects are about 20 nm, so resistance is now an urgent concern.

It aids to picture the electrons in an interconnect as a full established of balls on a billiards desk. Now imagine shoving them all from a single stop of the desk toward a further. A number of would collide and bounce in opposition to every other on the way, but most would make the journey in a straight-ish line. Now contemplate shrinking the desk by half—you’d get a ton far more collisions and the balls would go far more slowly and gradually. Upcoming, shrink it again and improve the number of billiard balls tenfold, and you might be in something like the condition chipmakers encounter now. Authentic electrons do not collide, automatically, but they get close adequate to a single a further to impose a scattering power that disrupts the stream as a result of the wire. At nanoscale dimensions, this prospects to vastly increased resistance in the wires, which induces significant electricity-shipping decline.

Growing electrical resistance is not a new problem, but the magnitude of improve that we are observing now with every subsequent course of action node is unparalleled. Additionally, traditional techniques of handling this improve are no longer an option, mainly because the production rules at the nanoscale impose so a lot of constraints. Absent are the times when we could arbitrarily improve the widths of certain wires in buy to battle growing resistance. Now designers have to stick to certain specified wire widths or else the chip might not be manufacturable. So, the industry is confronted with the twin complications of increased resistance in interconnects and significantly less room for them on the chip.

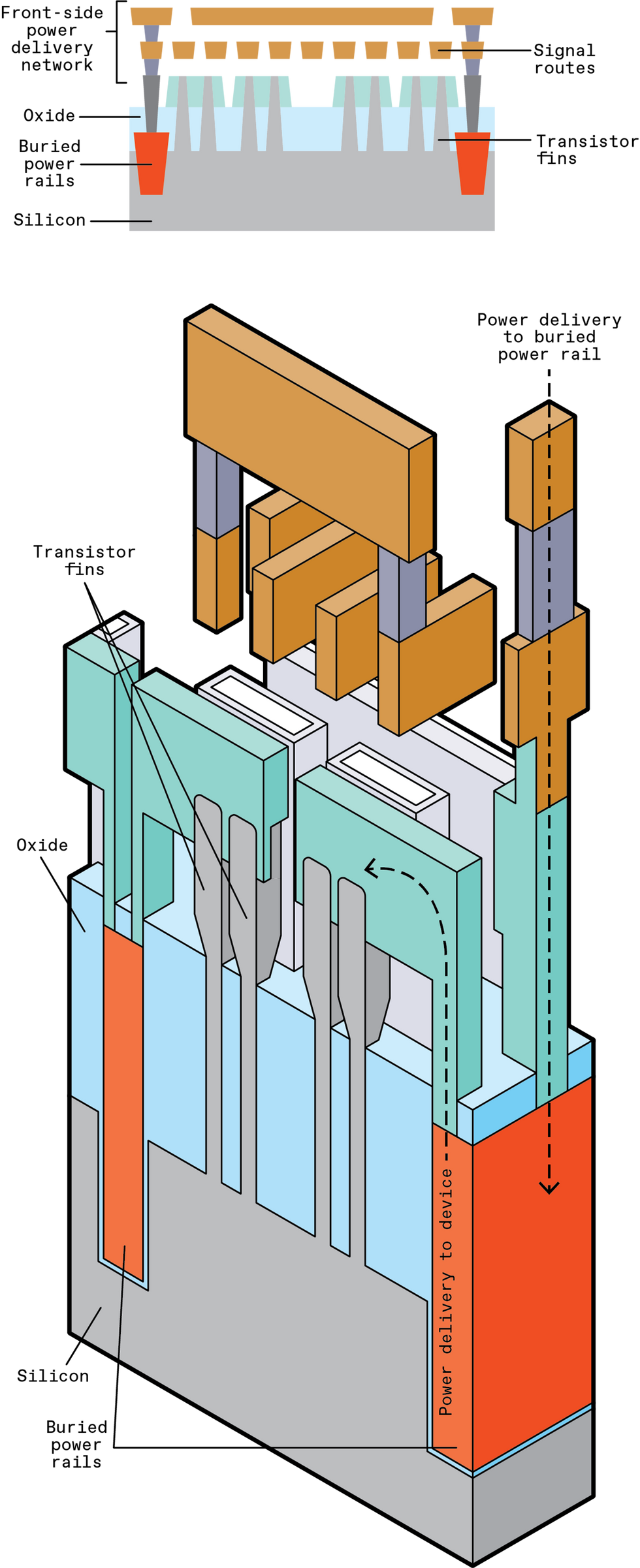

There is a further way: We can exploit the “empty” silicon that lies beneath the transistors. At Imec, where authors Beyne and Zografos work, we have pioneered a production thought identified as “buried electricity rails,” or BPR. The method builds electricity connections beneath the transistors in its place of earlier mentioned them, with the goal of producing fatter, significantly less resistant rails and liberating area for signal-carrying interconnects earlier mentioned the transistor layer.

To lower the resistance in electricity shipping, transistors will tap electricity rails buried within just the silicon. These are reasonably massive, reduced-resistance conductors that a number of logic cells could link with.Chris Philpot

To develop BPRs, you initially have to dig out deep trenches beneath the transistors and then fill them with metal. You have to do this prior to you make the transistors themselves. So the metal decision is vital. That metal will want to endure the processing measures used to make large-quality transistors, which can achieve about 1,000 °C. At that temperature, copper is molten, and melted copper could contaminate the entire chip. We have hence experimented with ruthenium and tungsten, which have increased melting points.

Considering the fact that there is so a great deal unused area beneath the transistors, you can make the BPR trenches vast and deep, which is fantastic for delivering electricity. When compared to the slender metal levels instantly on major of the transistors,

BPRs can have 1/20 to 1/30 the resistance. That indicates that BPRs will effectively allow you to provide far more electricity to the transistors.

Additionally, by shifting the electricity rails off the major side of the transistors you totally free up room for the signal-carrying interconnects. These interconnects kind basic circuit “cells”—the smallest circuit units, this kind of as SRAM memory bit cells or easy logic that we use to compose far more sophisticated circuits. By using the area we have freed up, we could shrink individuals cells by

sixteen percent or far more, and that could in the long run translate to far more transistors for every chip. Even if feature size stayed the same, we’d still thrust Moore’s Regulation a single action additional.

Regrettably, it appears like burying local electricity rails alone is not going to be adequate. You still have to convey electricity to individuals rails down from the major side of the chip, and that will price tag efficiency and some decline of voltage.

Absent are the times when we could arbitrarily improve the widths of certain wires in buy to battle growing resistance.

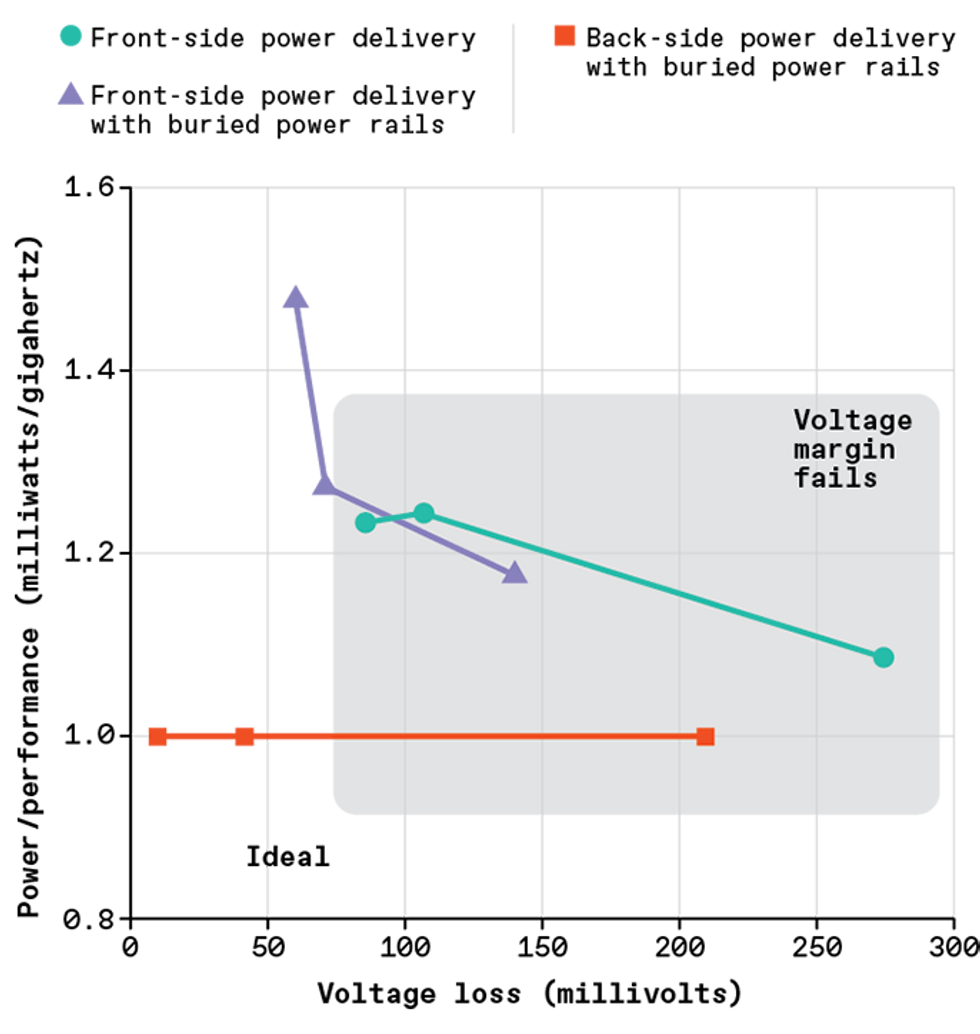

Researchers at Arm, such as authors Cline and Prasad, ran a simulation on a single of their CPUs and discovered that, by themselves, BPRs could allow you to develop a 40 percent far more effective electricity community than an everyday entrance-side electricity shipping community. But they also discovered that even if you used BPRs with entrance-side electricity shipping, the general voltage shipped to the transistors was not large adequate to maintain large-effectiveness operation of a CPU.

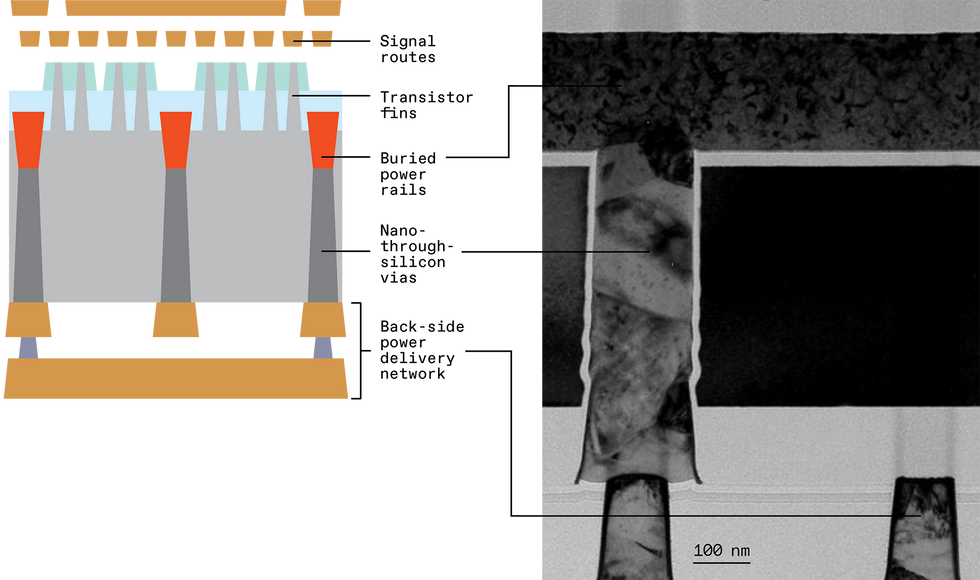

The good news is, Imec was concurrently developing a complementary option to additional boost electricity shipping: Shift the whole electricity-shipping community from the entrance side of the chip to the back side. This option is identified as “back-side electricity shipping,” or far more usually “back-side metallization.” It consists of thinning down the silicon that is beneath the transistors to 500 nm or significantly less, at which issue you can make nanometer-size “as a result of-silicon vias,” or

nano-TSVs. These are vertical interconnects that can link up as a result of the back side of the silicon to the bottom of the buried rails, like hundreds of very small mineshafts. As soon as the nano-TSVs have been developed beneath the transistors and BPRs, you can then deposit additional levels of metal on the back side of the chip to kind a comprehensive electricity-shipping community.

Growing on our before simulations, we at Arm discovered that just two levels of thick back-side metal was adequate to do the position. As extensive as you could area the nano-TSVs closer than two micrometers from every other, you could structure a back-side PDN that was 4 times as effective as the entrance-side PDN with buried electricity rails and 7 times as effective as the traditional entrance-side PDN.

The back-side PDN has the additional benefit of being physically divided from the signal community, so the two networks no longer compete for the same metal-layer assets. You can find far more room for every. It also indicates that the metal layer properties no longer want to be a compromise amongst what electricity routes desire (thick and vast for reduced resistance) and what signal routes desire (slender and narrow so they can make circuits from densely packed transistors). You can concurrently tune the back-side metal levels for electricity routing and the entrance-side metal levels for signal routing and get the finest of both equally worlds.

Transferring the electricity shipping community to the other side of the silicon—the “back side”—reduces voltage decline even far more, mainly because all the interconnects in the community can be made thicker to decrease resistance. What’s far more, eliminating the electricity-shipping community from earlier mentioned the silicon leaves far more room for signal routes, major to even smaller sized logic circuits and letting chipmakers squeeze far more transistors into the same location of silicon.

Chris Philpot/IMEC

In our designs at Arm, we discovered that for both equally the traditional entrance-side PDN and entrance-side PDN with buried electricity rails, we experienced to sacrifice structure effectiveness. But with back-side PDN the CPU was equipped to achieve large frequencies

and have electrically effective electricity shipping.

You may well, of class, be wondering how you get signals and electricity from the offer to the chip in this kind of a scheme. The nano-TSVs are the important listed here, as well. They can be used to transfer all enter and output signals from the entrance side to the back side of the chip. That way, both equally the electricity and the I/O signals can be attached to solder balls that are positioned on the back side.

Simulation scientific tests are a good start off, and they display the CPU-structure-stage opportunity of back-side PDNs with BPR. But there is a extensive highway forward to deliver these technologies to large-volume production. There are still significant components and production challenges that want to be solved. The finest decision of metal components for the BPRs and nano-TSVs is important to manufacturability and electrical efficiency. Also, the large-factor-ratio (deep but skinny) trenches essential for both equally BPRs and nano-TSVs are extremely tough to make. Reliably etching tightly spaced, deep-but-narrow attributes in the silicon substrate and filling them with metal is reasonably new to chip manufacture and is still something the industry is finding to grips with. Building production instruments and approaches that are reputable and repeatable will be vital to unlocking popular adoption of nano-TSVs.

Additionally, battery-driven SoCs, like individuals in your phone and in other electricity-constrained designs, currently have a great deal far more innovative electricity-shipping networks than individuals we have talked about so significantly. Contemporary-day electricity shipping separates chips into a number of electricity domains that can function at various voltages or even be turned off completely to preserve electricity. (See ”

A Circuit to Improve Battery Daily life,” IEEE Spectrum, August 2021.)

In assessments of a number of designs using 3 kinds of electricity shipping, only back-side electricity with buried electricity rails [purple] gives adequate voltage with no compromising effectiveness.Chris Philpot

Hence, back-side PDNs and BPRs are finally likely to have to do a great deal far more than just competently provide electrons. They are likely to have to exactly handle where electrons go and how a lot of of them get there. Chip designers will not want to just take a number of measures backward when it arrives to chip-stage electricity structure. So we will have to concurrently enhance structure and production to make positive that BPRs and back-side PDNs are much better than—or at least appropriate with—the electricity-preserving IC strategies we use these days.

The future of computing depends upon these new production strategies. Electric power usage is essential regardless of whether you might be worrying about the cooling monthly bill for a knowledge centre or the number of times you have to demand your smartphone every day. And as we go on to shrink transistors and ICs, delivering electricity turns into a significant on-chip problem. BPR and back-side PDNs might well answer that problem if engineers can conquer the complexities that appear with them.

This posting seems in the September 2021 print concern as “Electric power From Underneath.”