Copper Conformal Coating Tech Allegedly Crushes Traditional Heatsinks in Efficiency

Heatsinks are a staple of Computer system cooling technological innovation as we know it. Each passive and lively coolers make use of heatspreaders and heatsinks, but a workforce of scientists from the College of Illinois at Urbana-Champaign and the University of California, Berkeley (UC Berkeley) lately observed what appears to be like a significantly far better, all-encompassing, and sleeker remedy.

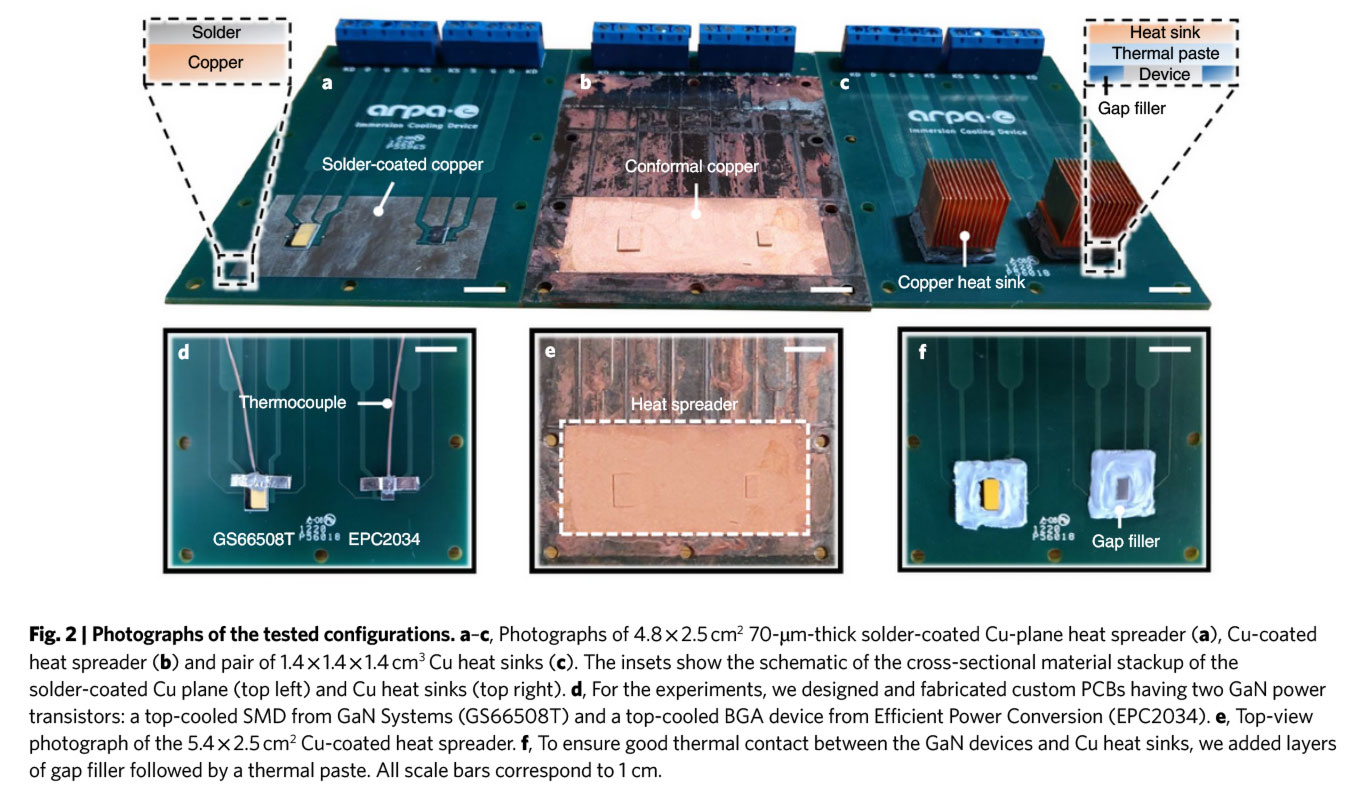

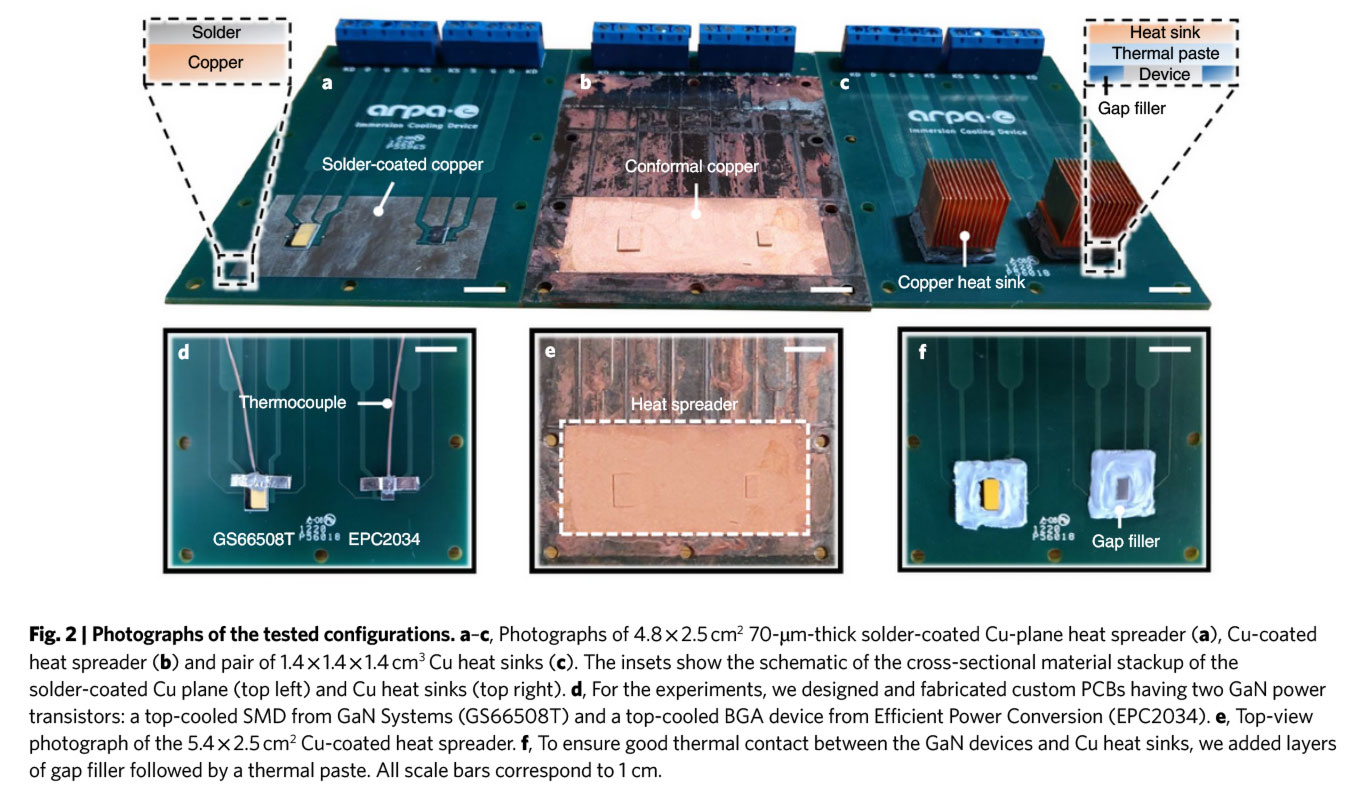

The researchers explain their experiments and findings in a paper (opens in new tab) entitled “Higher-efficiency cooling by using the monolithic integration of copper on electronic devices,” as noticed by Science Everyday. Highlights of the new copper conformal coating technologies are that it takes up minimal in the way of actual physical area in a device and that it is a lot extra economical than present-day copper heatsinks. The scientists shown a 740% improve in the electric power for each device volume.

There are a few primary issues with regular heatsinks, stated Tarek Gebrael, the direct creator of the paper and a UIUC Ph.D. pupil in mechanical engineering. First, the most state-of-the-art heatsinks working with exotic and very effective conducting supplies can be expensive and challenging to scale up. Gebrael mentioned heatspreaders that contains diamonds as one particular rival tech, clearly illustrating his place.

Next, regular types incorporate a heatspreader and heatsink in tandem, and “in many scenarios, most of the heat is created underneath the electronic gadget,” lamented Gebrael. Thirdly, the greatest warmth spreaders cannot be mounted immediately onto electronics but demand a thermal interface materials, inhibiting exceptional general performance.

So, how does the new technology handle all the over drawbacks of recent heat sinking approaches? The new heatsink coating handles the full machine, generating a big cooling surface area space.

“The method first coats the equipment with an electrical insulating layer of poly(2-chloro-p-xylylene) (parylene C) and then a conformal coating of copper,” claims the investigation paper. “This lets the copper to be in close proximity to the heat-making factors, doing away with the want for thermal interface elements and offering enhanced cooling efficiency when compared with current systems.”

This coating procedure does away with any massive outcrops of copper or aluminum, so it is a a great deal extra compact alternative to wick heat absent from fast-managing processors and memory. In accordance to the scientists, the thin conformal coating and lack of a bulky traditional heatsink supply a considerably larger power for every unit volume, up to 740% far better. “You can stack numerous far more printed circuit boards in the exact same quantity when you are employing our coating, as opposed to if you are employing common liquid- or air-cooled heat sinks,” asserted Gebrael.

The researchers future system to verify the coating’s durability, which is an important move to sector acceptance. On top of that, the scientists strategy to examination with immersion cooling and in significant voltage environments. For their preliminary checks, the researchers utilised “uncomplicated” PCBs, but they hope to scale up screening of the cooling tech on hotter jogging electronics like “total-scale energy modules and GPU cards.”

In summary, the technological innovation appears promising with no staying much too high-priced or intricate for ingredient makers to take into account for useful use. Right until this new warmth sinking tech comes, you will have to contend with common CPU cooling and GPU cooling.