Redox-Flow Cell Stores Renewable Energy as Hydrogen

“Hydrogen is a pretty excellent provider for this style of do the job,” states Wei Wang, who is the chief scientist for stationary vitality storage study at the Pacific Northwest National Laboratory in Washington. It’s an economical vitality provider, and can be quickly stored in pressurized tanks. When desired, the gasoline can then be transformed back into electrical vitality by means of a gas mobile and fed into the grid.

But h2o electrolyzers are high priced. They do the job below acidic conditions which call for corrosion-resistant metal plates and catalysts designed from precious metals such as titanium, platinum, and iridium. “Also, the oxygen electrode isn’t pretty economical,” states Kathy Ayers, vice-president of R&D at Nel Hydrogen, an Oslo-based business that specializes in hydrogen production and storage. “You drop about .three volts just from the reality that you are striving to change h2o to oxygen or vice versa,” she states. Splitting a h2o molecule needs an used voltage of 1.23 V.

In a bid to triumph over this challenge, Nel Hydrogen and Wang’s crew at Pacific Northwest joined forces in 2016, right after acquiring funding from the U.S. Office of Energy’s Advanced Investigation Assignments Agency-Energy. The option they’ve appear up with is a gas mobile that acts as both of those a battery and hydrogen generator.

“We get in touch with it a redox-move mobile simply because it is a hybrid between a redox-move battery and a h2o electrolyzer,” clarifies Wang.

A redox-move battery, in essence a reversible gas mobile, is typically designed up of a positive and unfavorable electrolyte stored in two independent tanks. When the liquids are pumped into the battery mobile stack situated between the tanks, a redox response takes place, and generates electrical energy at the battery’s electrodes.

By comparison, the new creation has only 1 electrolyte, comprised of an iron salt (instead than the much more frequently made use of vanadium) dissolved in acid. When hydrogen ions react with the iron salt (Fe2+), hydrogen gasoline is created at the platinum-coated carbon cathode in the battery stack.

“We introduce iron as a middleman, so we can independent electrolysis into two reactions,” states Wang. Doing so permits 1 to control exactly where and when to reverse the response to develop electrical vitality to source to the grid. “The system offers you flexibility… you could do the regeneration through evening time when electrical energy rates are at a peak,” he states.

Regenerating Fe2+ in the reverse response also permits for the constant production of hydrogen gasoline, he states. “And simply because the hydrogen-iron mobile makes use of about half the voltage of a traditional electrolyzer, you can generate hydrogen at a a great deal cheaper price if you do all the things proper.”

It also assists that iron is a great deal cheaper and much more plentiful as opposed with vanadium.

Qing Wang, a resources scientist at the National University of Singapore, sees yet another advantage. “If you care much more about purity and want to have extremely-pure hydrogen, then perhaps it is a excellent option,” he states. Cross-contamination can often occur through electrolysis simply because the hydrogen and oxygen gases created are so compact that they are capable to traverse the membrane separator.

The new redox-move mobile executed properly in lab assessments, exhibiting a cost capacity of up to 1 ampere for each sq. centimeter, a ten-fold boost more than regular move batteries. It was also capable to face up to “several hundred cycles” of charging, which has in no way been demonstrated before in hydrogen ion move batteries, states Wang, who has a range of patents for the creation, with a few much more pending.

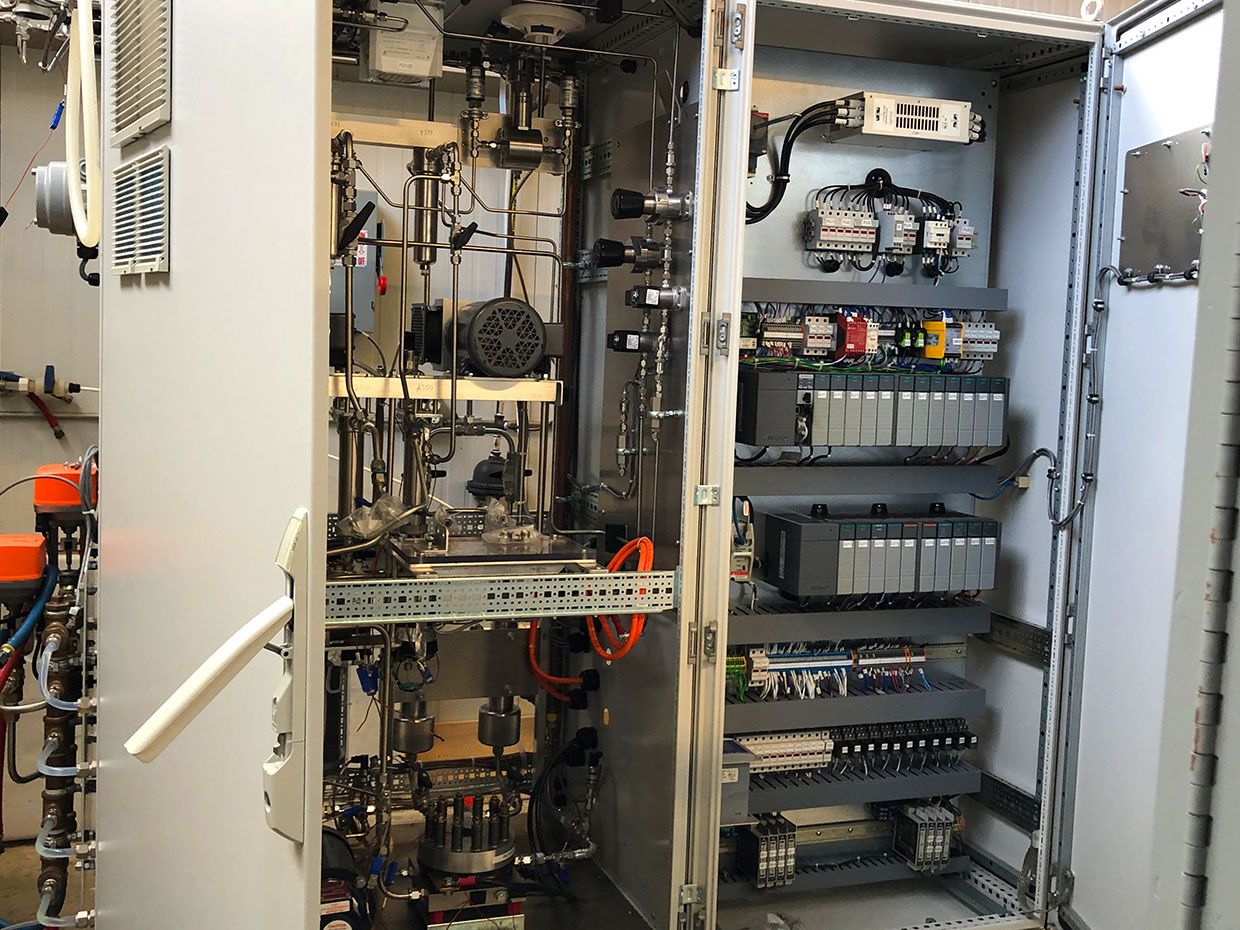

While the PNNL crew experimented on a solitary mobile measuring 10 sq. centimeters, Ayers and her colleagues at Nel Hydrogen proved that the know-how could do the job even when scaled up to a five-mobile stack measuring a hundred sq. centimeters. They plan to devote the next few months fine-tuning the system and eradicating kinks, such as how to lower destruction to the pumps brought on by the acidic electrolyte, before commercializing it.

This post was updated on twenty April 2020.