Graphene Solar Thermal Film Could Be a New Way to Harvest Renewable Energy

Suppressing thermal emission loss—also identified as blackbody radiation—while simultaneously absorbing solar mild is critical for an productive solar thermal absorber but is really complicated to obtain, states Baohua Jia, founding director of CTAM. “That’s since, based on the absorbed heat and homes of the absorber, the emission temperature differs, which qualified prospects to important variations in its wavelength,” she explains. “But we’ve produced a 3-dimensional structured graphene metamaterial (SGM) that is really absorbent and selectively filters out blackbody radiation.”

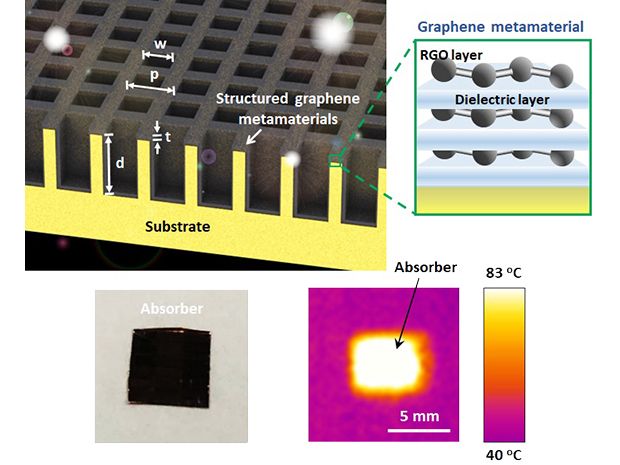

The 3D SGM is composed of a thirty-nanometer-thick movie of alternating graphene and dielectric layers deposited on a trench-like nanostructure that does double obligation as a copper substrate to enhance absorption. Additional importantly, the substrate is patterned in a matrix arrangement to enable adaptable tunability of wavelength-selective absorption.

The graphene movie is made to take in mild involving .28- to two.five-micrometer wavelengths. And the copper substrate is structured so that it can act as a selective bandpass filter that suppresses the usual emission of internally generated blackbody electricity. This retained heat then serves to more raise the metamaterial’s temperature. For this reason, the SGM can speedily heat up to eighty three levels C. Need to a unique temperature be needed for a particular application, a new trench nanostructure can be fabricated and tuned to match that particular blackbody wavelength.

“In our prior do the job, we demonstrated a ninety nm graphene heat-absorbing material,” states Baohua. However it could heat up to 160 levels C, “the structure was more complicated, [comprising] 4 layers: a substrate, a silver layer, a layer of silicon oxide, and a graphene layer. Our new two-layer structure is more simple and doesn’t have to have vacuum deposition. And the process of fabrication is scalable and low charge.”

The new material also uses less graphene by drastically reducing the movie thickness to one 3rd, and its thinness aids in transferring the absorbed heat more proficiently to other media these kinds of as water. Additionally, the movie is hydrophobic, which fosters self-cleansing, even though the graphene layer efficiently protects the copper layer from corrosion, serving to to lengthen the metamaterial’s life time.

“Because the metallic substrate’s structural parameters are the most important variables governing over-all absorption general performance of the SGM, fairly than its intrinsic functions, unique metals can be utilised in accordance to application requirements or charge,” states Keng-Te Lin, guide creator of a paper on the metamaterial just lately posted in Nature Communications, and who is also a investigation fellow at Swinburne College. Aluminum foil can also be utilised to replace copper without having compromising the general performance, he notes.

To test the metamaterial’s design and stability, the scientists fabricated a prototype working with regular laser nanofabrication, self-assembly graphene oxide coating, and photograph-induced reduction.

“We utilised the prototype movie to generate clean water and realized an remarkable solar-to-vapor performance of 96.two p.c,” states Keng-Te. “This is extremely competitive for clean water technology working with a renewable electricity source.”

He provides that the metamaterial can also be utilised for electricity harvesting and conversion apps, steam technology, wastewater cleansing, seawater desalination, and thermoelectricity technology.

One obstacle nevertheless remaining is locating a manufacturing process for earning the substrate scalable.

“We are doing work with a personal firm, Innofocus Photonics Engineering, that has commercialized a coating machine to lay down the graphene and dielectric layers,” states Baohua. “And we are pleased with that. What we are now hunting for is a appropriate process for huge scale manufacturing of the copper substrate.” One risk, she provides, is working with a roll-to-roll method.

In the meantime, the scientists are continuing to fantastic-tune the nanostructure design and improve the SGM’s stability and absorption performance. “As for commercialization,” states Baohua, “we feel that will be feasible in one to two yrs.”